Volant Throttle Body Spacer Review and Dyno Test

Jamie Alberico | Oct 01, 2012 | Comments 9

In the days before electronic fuel injection systems, throttle body spacers were pretty common. They were a quick, easy way to add power to your carbureted or TBI (throttle body injection) vehicle. Today, with the advent of multi-port electronic fuel injection, the benefits of a throttle body spacer are a bit more dubious.

In the days before electronic fuel injection systems, throttle body spacers were pretty common. They were a quick, easy way to add power to your carbureted or TBI (throttle body injection) vehicle. Today, with the advent of multi-port electronic fuel injection, the benefits of a throttle body spacer are a bit more dubious.

Our own Rob Eckhart decided to answer the question once and or all – Do throttle body spacers really work? – and tested a Volant Vortice TBS on his own 2nd generation Tundra.

Here are the results of that test and our analysis.

What is A Throttle Body Spacer?

Before the days of multi-port fuel injection, a throttle body spacer (TBS) was a good power add-on. Placed between the carburetor and the air intake, the increased distance allowed more space for the air and fuel to mix before going into the intake manifold and down into the cylinders. If the carburetor was tuned correctly – and if the thickness of the spacer was correct – a TBS was a pretty solid performance add-on, especially for the money.

For the last 15 years or so, auto manufacturers have used multi-port electronic fuel injection systems (also known as multi-point fuel injection) that typically inject fuel into the air stream inside the intake manifold immediately before it’s sent down into the cylinder. Since the throttle body is a few inches upstream of this point, adding a spacer between the throttle body and the intake manifold really shouldn’t have any benefit…it’s like adding an extra inch or so of length to the intake system.

If you’re a regular reader TundraHeadquarters, you’ve probably already read our article Stay Away From Throttle Body Spacers, which spells out why we don’t believe in the power of throttle body spacers on modern fuel-injected vehicles.

Still, many truck owners are perhaps fondly reminiscent of the benefits of a throttle body spacer, so Rob took the time to install and dyno test a Volant throttle body spacer on his 5.7L Tundra.

Throttle Body Spacer Installation

Volant’s Vortice Throttle Body Spacer boasts a lightweight nylon composite design, a bargain price (right about $50) and a supposedly quick 20 minute install time*. The kit comes with a 1” Throttle Body Spacer, a gasket, installation hardware, and detailed instructions with pictures.

*Supposedly, as in not true for us.

Volant Throttle Body Spacer Installation: Assessing Kit Contents

To install the Volant TBS, Rob removed the engine cover (no hardware required, just lift and set aside), then loosened the air intake hose clamp at the throttle body and slid it back.

He then loosened and removed four 10 mm bolts on the throttle body and removed it from the manifold.

The Volant TBS was inserted with the gasket between the OE throttle body and intake. It is very important to note which direction on the TBS has a raised inner edge. This edge must face the throttle body and not the intake.

Using the provided hardware, Rob reinstalled the Throttle body with the spacer onto the intake and tightened the bolts, taking care not to over torque them.

After reattaching the air intake and tightening the hose clamp, the install was done.

Pros and Cons of Install

Pros:

- All the hardware was included along with detailed instructions that anyone can follow.

- Install didn’t require any additional modifications to the surrounding engine area

Cons:

After drilling the holes, the TBS finally aligned properly for all four screws to thread.

- The biggest problem Rob found with the Kit was that the bolt spacing pattern was not precise to the OE throttle body. After 45 minutes and multiple attempts, Rob was only able to get 3 of the 4 bolts to thread correctly.

- The only remedy found was to increase the hole size by drilling the spacer mounting points to allow for all bolts to correctly install. Boring out the holes 1 size larger & beveling provided the necessary space to reinstall correctly. It was possibly a quality control issue at the factory (we all have bad days, right?) but without an additional unit to compare, Rob was left to shake his fist at the car gods and “mod the mod” to make it work. So much for a 20 minute install time!

About The Dyno Testing

Before we get much further, we should talk about the testing process. Rob’s drive to the dyno test site took about two hours. While Rob took a break and gave his truck engine a chance to cool off before testing, the engine was still pretty warm when Rob parked on the dyno’s giant roller (a dyno is basically a treadmill for cars, just in case you didn’t know). Rob did a few runs, got some baseline data, and then left the dyno shop to install the throttle body spacer. Rob returned later in the day (when his engine was even cooler) and ran the tests again.

While our testing data showed that Rob’s truck gained quite a few horsepower after installing Volant’s throttle body spacer, we feel pretty confident saying that the results we’ve measured aren’t indicative of the power the throttle body spacer adds…but more on that below.

Testing Results

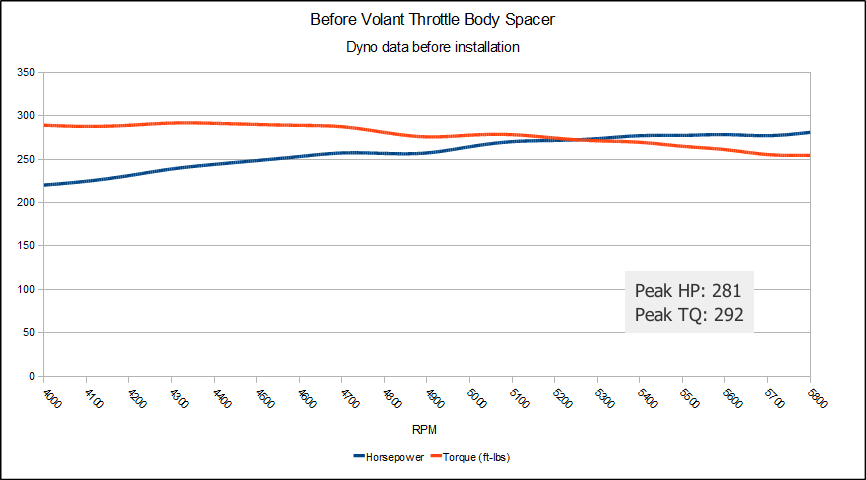

Before Volant’s Vortice Throttle Body Installation Rob’s Tundra had a peak horsepower of 281 and a peak torque of 292. The dyno data in the graph below was the average from three individual runs on the Dyno track, both before and after installation.

Dyno test data before Volant Throttle Body Spacer iunstall

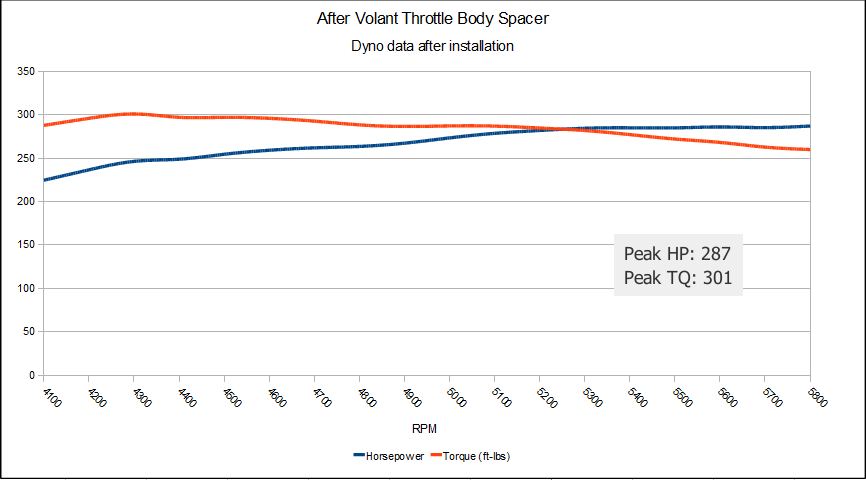

After installing the TBS, Rob’s Tundra had a peak horsepower of 287 and a peak torque of 301. That’s an addition of 6 horsepower and 9lbs-foot of torque.

Dyno test data after install – we saw an increase in power, but the standard deviation on our 2nd run of tests was quite a bit higher than our 1st run.

Analysis

Let’s start by saying the data in our charts shows horsepower at the rear wheels, not flywheel horsepower, so the peak HP and Torque numbers are quite a bit lower than what Toyota advertises (which is always flywheel power). Most vehicles loose about 20% of their rated horsepower between the fly wheel and the pavement. Additionally, remember that the engine was warm during the baseline testing…which means that, even before we ran the Volant TBS Dyno, the odds were already in it’s favor.

After the addition of the Volant Throttle Body Spacer, Rob saw an additional 6 horsepower and 9lb-ft of torque than in the control test. HOWEVER, this is suspect because:

- The engine temp was undoubtedly lower during the 2nd set of runs

- The standard deviation of our “before data” was pretty decent – about 3hp and 3lb-ft of torque. The standard deviation of our “after” data is larger – 5hp and 6hp-ft of torque to be exact.

- Put another way, the margin of error on our ‘after’ data is much higher. The actual results for our “after” Dyno test may have been as high as 292 HP or as low as 282 HP. Our Control test showed a peak horsepower of 281– only 1hp higher than our hot engine!

It seems reasonable that the Volant Vortice TBS had a minimal positive effect on the performance of the vehicle. At best, (assuming the margin of error and minimal loss of torque and horsepower from the heat during our control test), the Volant TBS is good for a couple of horsepower and a pound-foot of torque. At worst, these throttle body spacers have no effect.

Bottomline

While our testing did show that the Volant throttle body spacer added power, we have a lot of reasons to be skeptical. Furthermore, the fact remains that the throttle body spacer didn’t install correctly – Rob had to drill it out to make it work, and even then it was too tight to get all four bolts into the throttle body.

Unfortunately, we’ve seen this same kind of quality problem with another Volant product…the Volant cold air intake kit we reviewed all the way back in 2007. Much like the throttle body spacer, many of the people who made comments on our Volant air intake review noted that there were major quality issues with the intake (the piping on Volant’s kit didn’t fit). While we’ve only tested two Volant products over the years, both of these tests left us less-than-impressed in terms of quality…and some friends at a popular aftermarket accessory website have told us that Volant quality isn’t as high as competing products.

Therefore, considering the quality, all the data, and what we know about the fuel-air mixing process, we have to say that this throttle body spacer isn’t worth buying. We do not recommend it.

Search terms people used to find this page:

- tundraheadquarters

- Throttle Body spacer

Filed Under: Toyota Tundra Accessories

Something doesn’t seem right to me.

The HP and TRQ numbers seem low for the 5.7. What was the altitude for the Dyno test? A few thousand feet or so?

So you’ve got about 20% driveline loss (that’s a standard estimate), plus Rob has a big set of wheels and tires and likely zap some HP too. If you just figure the driveline loss, you’re at 306. Pull another 20 hp off for wheels and tires (the tires aren’t just big – they’re wide too so lots of friction) and then add some power back b/c of intake and exhaust and you end up right about where we tested, give or take a few HP.

I had a feeling it may have been larger tires! That was my second guess.

Thanks for the follow up 🙂

One thing also to keep in mind is that according to tests performed by Truck Trend and K&N have shown the 5.7 to be a good bit less powerful than advertised by Toyota.

Interesting…they use a standard SAE test to measure flywheel horsepower, so perhaps the driveline isn’t as efficient as the drivelines on other trucks?

Very imformative Jason. Good to know if it’s worthy or not. I’m glad an AFE came in when I thought I ordered a Volant. Didn’t have any Issues with the AFE Stage II but the instructions were crappy.

Awesome, but don’t thank me – thank Jamie (it was her first post).

The numbers the TBS added at the dyno sound so promising, just curious do they compare to what Volant advertises for actual increases..?

Hey just wanted to add that it was bc of your earlier review on the AFE cai that I chose the AFE, and I couldnt have been happier…

Ive been following TundraHeadquarters since I bought my Tundra lil over a year ago, and its a great site, with tons of “real” helpful info and great reviews…really lookin forward to the new writers, and changes…

Thanks (jason) and everyone….for all the great help you’ve given me and other tundra owners..!!

I recently installed both a Volant CAI and throttle body spacer on my 5.7 Tundra. The CAI install went fairly well, so Volant may have addressed the issues noted in your 2007 install. However, I had the exact same problems you had with the TBS, including about the same time struggling with two or three bolts lining up (along with appropriate language) and arrived at the same solution (drilling the holes oversize). For the dyno test, it sounds like the after results are suspect as the engine was cooler. It seems the solution to compare apples to apples would be to warm up the engine, similar to the before runs, and repeat the test. Is the higher variation on the after runs due to the engine warming up as more runs were done? It would be nice to see before and after dyno runs without the engine temperature variation. Thanks.