2011 Prius vs 1993 Geo Metro

I like to read as many auto blogs as possible, and occasionally I find something that strikes a chord with me. About a week ago, Christopher Demorro at Gas2.org lamented that the Prius isn’t advanced enough and that it was “falling behind.”

Christopher’s argument (which you can read at the link above) goes a little bit like this:

- Toyota had a 10 year jump on everyone in the segment that they didn’t take advantage of

- Toyota’s latest gen Prius only gets 50 mpg, which isn’t much better than the 40mpg Focus, Fiesta, Cruze, Elantra, etc.

- Toyota’s new Prius minivan was an obvious need years ago – why didn’t Toyota do it sooner?

While I’m not qualified to judge other auto writers for tearing down a manufacturer’s decision making – I do it all the time myself – Christopher’s whole rant against the Prius is poorly considered. I told him as much in the comments, we went back and forth, and here’s what we’ve come to:

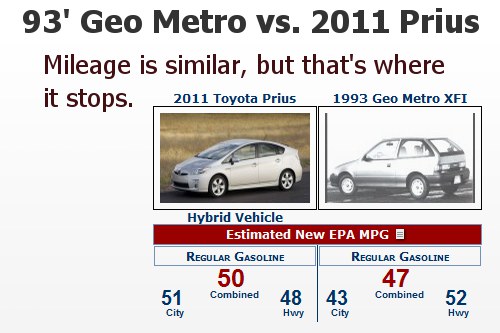

93 Geo Metro XFI vs 2011 Toyota Prius - Gas Mileage Is Similar, But That's It

Christopher says he’d rather have a 93′ Geo Metro XFI than a 2011 Toyota Prius, since they both get about the same mileage and the Metro is cheaper and easier to fix.

if you put a Toyota Prius and a Geo Metro in front of me, and told me I could have either car…I’d probably take the Geo. It isn’t safer, or faster, or better looking, but it is simpler with an equivalent MPG.

OK Christopher you asked for it. Here’s why I say that’s ridiculous:

2011 Tundra Gets 4 Star Overall Crash Test Rating, Tied For First In Segment

Last updated 3-17-2011

NHTSA has released their crash test ratings for many of the 2011 half-tons on the market – here’s a summary of the ratings.

So far, it looks like the 2011 Tundra is the safest half-ton on the market, with only the narrowest lead over the GM trucks as a result of the Tundra’s superior IIHS test results. The F150 and Ram come in to third and fourth place respectively (the Nissan Titan has not been rated by NHTSA, so it’s not included in our comparison). Read more…

Libyan Police Use Toyota Tundras

It might not be the most flattering endorsement of a Toyota product, but here it is: a New York Times article features an image of riot police rolling down the street in armored blue Toyota Tundras.

New York Times photographers captured these Libyan police using Toyota Tundras - click the image to see the original story

The question is, who sold the Libyans these trucks? The only thing worse than a North African dictator using a made-in-the-USA pickup to crush rebellion is using a made-in-the-USA pickup that was potentially sold by a US police vehicle upfitting business. Read more…

CalTrend Seat Covers for the Toyota Tundra

Seat covers have come a long way since the days of fuzzy faux-fur and cheap elastic straps. These days, if you are tired of the look of the seats in your Toyota Tundra you can choose between a bewildering variety of materials with which to recover each throne, ranging from basic patterns all the way up to form-fitting full leather sleeves.

One of the biggest seat cover manufacturers currently on the market is CalTrend, which has been in the accessory business for more than two decades. Based out of California, CalTrend is most notable for the fact that it produces a startlingly wide range of custom-fitted seat covers…it is possible to select from 11 different cover materials.

CalTrend Seat Covers – A Materials Breakdown

The seat cover fabrics used by CalTrend can be roughly lumped into a few specific categories. Read more…

Tundra Tool Box Buying Tips

When Jason was at SEMA this year he was able to speak to several different representatives from truck tool box companies about the details of their various products. What emerged from the interviews was a series of interesting takes on what goes into making a solid, safe and secure tool box for the truck bed of your Toyota Tundra. With that information in mind, we’ve put together a brief tutorial to help you use this knowledge to your advantage when selecting a tool box of your own. Special thanks to the video assist from Orion Newman of Better Built tool boxes.

Materials and Design

One of Orion’s main recommendations was to choose a tool box built out of a single piece of aluminum, reducing the number of welds to a bare minimum. Obviously there is the need to fully weld each of the five lower pieces of the box to each other, but aside from that each “side” of the box should be cut from a single piece of metal. This dramatically improves the overall strength of the box. Read more…