THQ Tours Toyota Motor Manufacturing Texas Plant in San Antonio, Texas

Tim Esterdahl | Sep 20, 2016 | Comments 6

A common topic of discussion among Toyota Tundra and Tacoma fans is the Toyota Motor Manufacturing Texas (TMMTX) plant. Specifically fans want to know how the trucks get built, what the product mix is and how much capacity the plant truly has. Recently, Toyota flew me down to San Antonio, Texas to learn all of that and more.

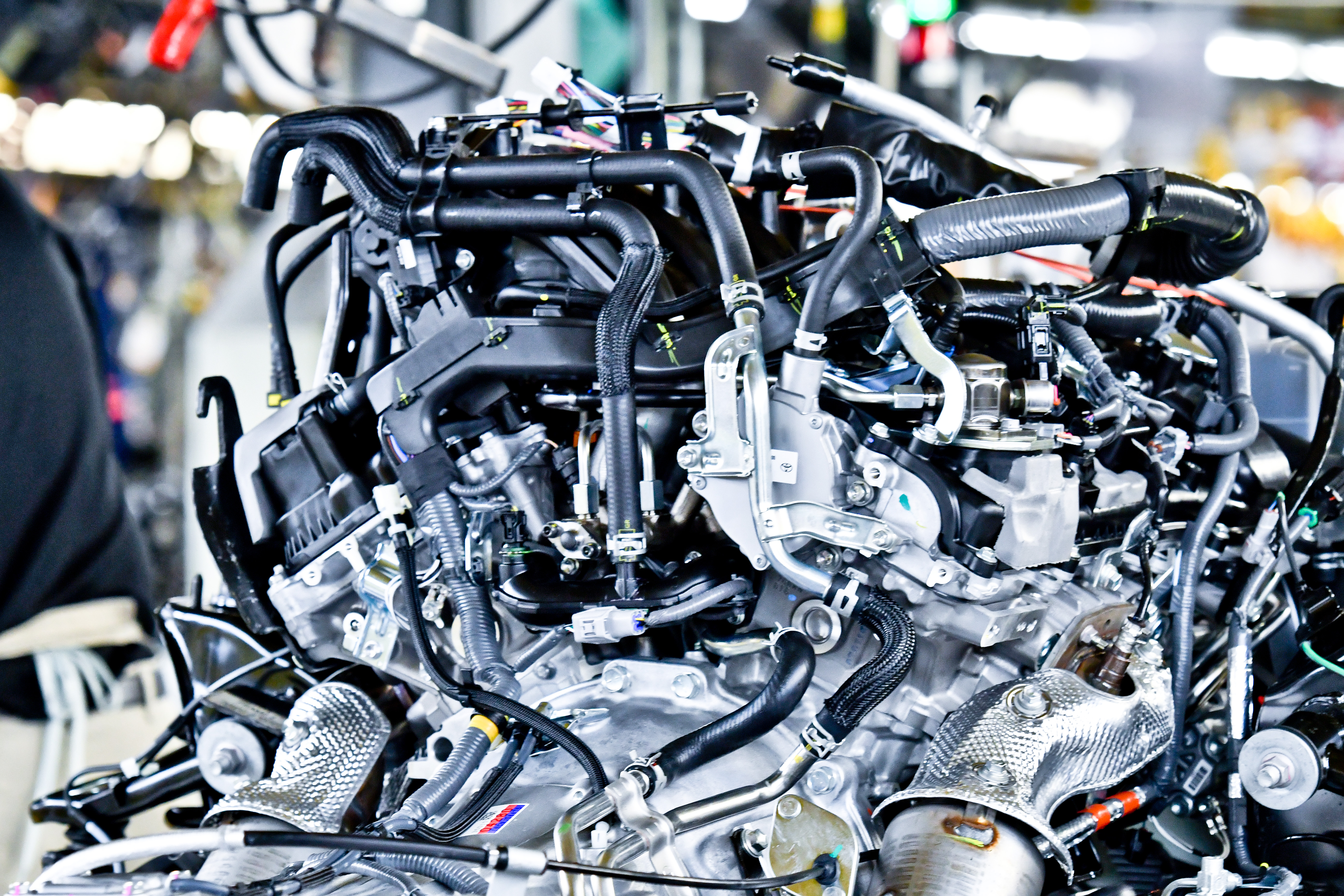

A recent tour of the Toyota Motor Manufacturing Texas plant really showed how well the Tundra and Tacoma are built.

The TMMTX plant sits on the south side of San Antonio, Texas and really does occupy an old ranch (the 1794 moniker comes from this). It sits upon 2,000 acres of land and outside of the 2 million square-foot plant there are still some old buildings from the ranch Toyota has chosen to leave standing. While the buildings provide some interesting dialogue, they are not safe to tour and are in different stages of falling in.

Now THIS is how you put wheels on!

Entering the TMMTX Plant

Passing through a security booth, the plant’s immense size is the first thing that grabs your attention. The second is more subjective for me. Let me explain. I visit plenty of manufacturing facilities and one of the things I’m always looking for is what vehicles the employees drive (I do the same thing at dealerships). My reasoning is simple: if the employees don’t believe in the product and personally own it, then why would consumers buy it? While this isn’t always the case since employees come and go and one can’t expect them to sell their old vehicle when starting at a new job, I do think it is still a good gauge of the product. Plus, the variety of vehicles can also speak to employee turnover. (note: photography is not available due to privacy concerns.)

After surveying the parking lot, I saw row after row filled with Toyota product and ALL the Tundra trucks featured the “Built in Texas, By Texans” sticker. Incidentally, I’ve been really surprised each time I’ve gone to Texas in the past year at seeing so many Tundra trucks on the road.

Walking through the doors, the lobby has a Tundra and Tacoma on display as well as an award’s case. I’m a voter for some of these awards and it is interesting to see them on display. After scanning the lobby, Toyota staff guides the group of journalists, myself included, into a conference room to don ear plugs, steel-toe shoes and get a briefing. Then, it is on to the tour.

Watching robots work is pretty fascinating.

The Guided Tour

While I’m not often sure what I’m always staring at, I’m a manufacturing nerd really and love checking out how things are built especially trucks. I’ve toured Boeing, Nissan and many GM facilities. Many of these plants have things in common like moving assembly lines, safety lines to walk, workers trading off jobs and parts bin constantly refreshed. TMMTX is no different.

Throughout the tour, the assembly lines is in constant movement moving the vehicle to the worker rather than the worker walking to the truck. This allows them to complete their job before the truck moves to the next person. It is incredibly efficient and, as the story I was told by Boeing goes, Toyota was one of the pioneers of this system and shared its assembly line knowledge with Boeing. The aircraft builder uses the moving line as well with the massive planes moving really slowly throughout their plant. Toyota uses the same philosophy, as do other plants these days, and a new Tundra or Tacoma rolls out of the factory about every 26 hours.

All sorts of different cab configurations, trim levels and Tundra/Tacoma models pass down the line.

Quality checks this one are very common throughout the assembly process.

Lastly, the Kaizen philosophy is in full effect. Kaizen is Toyota’s core belief in continual improvement. This is evident along the line where there are different wires hanging overhead. At any point, an employee can pull the line to either indicate a problem, indicate a quality issue with the truck and/or pull the line to alert their supervisor of a way to improve the production assembly. At the end of the day, the supervisors get together to discuss each time someone pulled the line and discuss ways to improve the process with the employees feedback. Then, the next day, they implement changes. This dynamic improvement helps improve the entire process and creates happy employees who feel empowered by their work.

Flex Schedule and Staffing

One of the interesting parts of the TMMTX plant is the fact it sits in a non-industrial area. This is farm and ranch country. Hiring, training and developing assembly workers has been a constant challenge for TMMTX and it is also why it takes them time to ramp up to a third-shift. It simply takes time to find those employees. Also, keeping these employees is a big reason why the TMMTX plant found creative ways to keep the employees working during the downturn in 2009 when the plant basically shut down for several months. Employees did mock runs, maintenance and even community projects to keep a steady paycheck coming.

While I saw a lot of smiles on the tour, one does wonder how long morale will hold up with the schedule.

This focus on employees is allowing Toyota to develop alternative working schedules like their current flex schedule with workers adding a Saturday shift and a floating day off. This schedule allows Toyota to effectively add a third-shift by floating days off for employees. It also reduces some of the wear and tear of the machines which, like anything, wear out through excessive use. Toyota says they hope to keep this schedule going, however, they are keenly aware their employees may very well get tired of the floating day off. The news of the Tijuana manufacturing expansion is welcome news to TMMTX. If this expansion goes as planned and the market cools a bit, their employees could get a respite from the flex schedule.

This focus on employees is allowing Toyota to develop alternative working schedules like their current flex schedule with workers adding a Saturday shift and a floating day off. This schedule allows Toyota to effectively add a third-shift by floating days off for employees. It also reduces some of the wear and tear of the machines which, like anything, wear out through excessive use. Toyota says they hope to keep this schedule going, however, they are keenly aware their employees may very well get tired of the floating day off. The news of the Tijuana manufacturing expansion is welcome news to TMMTX. If this expansion goes as planned and the market cools a bit, their employees could get a respite from the flex schedule.

Finally, one item really caught my attention. There are several TV screens in the facility as well as other materials that talk about the automotive segment – recent sales, top stories, etc… It was interesting to me to see how much the employees are engaged with their industry and how they keep up on the latest news. In fact, I would wager many of them read this blog – so… good job ladies and gentleman! I was impressed.

One of these days, I hope to make a trip to the Indiana facility as well as other manufacturing plants. What do you think? Which assembly plant would you like to see?

BONUS

The Million Mile Tundra got lots of attention from three waves of journalists.

- While I saw a lot of smiles on the tour, one does wonder how long morale will hold up with the schedule.

Search terms people used to find this page:

- tundraheadquarters

Filed Under: Tundra News

A tour of the plant is on my bucket list. Someday, plan to make the trip.

No question the assemble is first class. My Tundra has held up better than any truck I have owned before; in a class all by itself.

I’d be curious to see how the Tijuana plants compares to San Antonio.

That would be really interesting.

-Tim

Thanks for building this beautiful car!

Greeting’s from Switzerland

I used to have a contract gig (IT, not mfg) at the Toyota Forklift plant in Columbus, Indiana. I imagine it is similar to what you saw. Clean, quality, etc. One thing I noticed was the nursery rhyme music constantly playing in the background. Was that going on at TMMTX? (BTW, they use a 4 or 5 letter acronym for all of their plants including industrial mfg). Also, as I understood it, every mfg facility ties into the same AS400 mainframe system globally and that system runs the mfg process. In Indiana they used a separate SAP instance (ERP software, does ordering, billing, etc.) but everyone interfaces into the AS400 system in Japan for mfg. That system drives the production you see on the floor. And only the Japanese are allowed to modify it. Others can extract data from it or interface from it, but only the Japanese in Japan can touch it – very tight control.

Anyway, some interesting nerdy IT stuff for those interested.

Yep, the nursery rhyme music is an audio code for supervisors to know the status of the line. When someone pulls the cord, the music changes and a supervisor is able to “hear” where the problem is.

-Tim