Aluminum Tailgates? Closer Than You Think

Tim Esterdahl | Jul 16, 2012 | Comments 6

Automakers trying to meet higher MPG standards are increasing using aluminum instead of steel for all sorts of parts for weight reduction. The change is coming very soon with the next generation Chevy Silverado expected to use an aluminum hood. More aluminum items are expected to quickly follow.

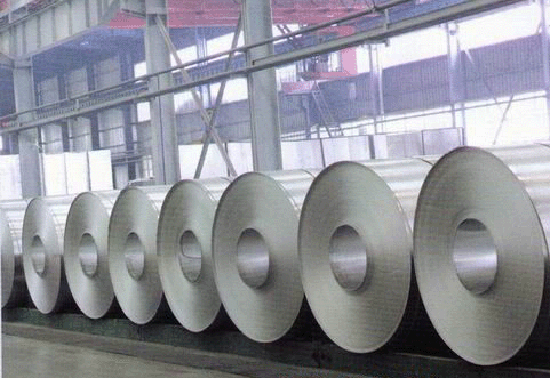

Aluminum manufactures and automakers are working to incorporate more aluminum into cars/trucks to meet new MPG regulations.

According to a story on Autonews.com, aluminum manufacture Alcoa Inc. is investing $300 million to expand aluminum sheet output in their Davenport, Iowa plant. While, another major manufacture Novelis Inc., plans to spend $200 million in its plant in Oswego, N.Y. Why? To meet rising demand from automakers.

The current administration proposal for fuel efficiency is 54.5MPG by 2025 model year. This means that cars/trucks need to dramatically lose some weight. The easiest way to do that is by expanding the use of aluminum in them. Currently, automakers have used aluminum for wheels, engine blocks, heat exchangers and suspension systems. Now they are starting to use it for hoods, tailgates, body panels and even pickup beds.

The big problem for consumers though is that aluminum costs more than steel. A lot more. A pound of raw aluminum is roughly twice that of steel. This means cars/trucks could cost a $1.50 more per pound. When you consider that some manufactures are expecting to decrease the overall weight of a vehicle by 800 pounds, it would be a $1,200 increase (if not more).

The next generation Chevy Silverado’s plan to use an aluminum hood will save about 25 lbs in weight according to the Autonews story. It remains to be seen how much more the truck will cost though.

Why the rush to use alumiunum in trucks? Autonews says:

Aluminum sheet could be especially useful for full-sized pickups, which will have to shed as much as 800 pounds to meet fuel economy standards, according to Richard Schultz, managing director of Ducker Worldwide. Schultz estimates that automakers will be able to make those weight reductions by 2020.

An 800 lbs savings in weight would translate to a 10% improvement in fuel economy, and if the vehicle is driven for 6 years and 100k miles, the extra cost up front will more than be paid for by fuel savings. If this sounds familiar, this is the currently the same line of thinking with regards to electric cars (see: Prius vs. Corolla).

One other thing to note, all that aluminum in an old vehicle has substantial salvage value – aluminum scrap could sells for as much as 10 times the price of scrap steel (that’s how it was back in 2007)…meaning that you just might get a portion of that initial $1200 investment back when you eventually have to scrap your old truck.

What do you think? Will aluminum be the future of automobile manufacturing?

Related Posts:

Filed Under: Auto News

When crash tests are done we will see how this will turn out. Not just the cost of buying will increase, your insurance for sure will increase. They have to account for the increase in price for the aluminum. You will save in gas but everything else will increase. So where is the real savings?

Mickey,

Good thought.

-Tim

Auto makers have been doing little things like this for years like you said in the article. Major downside is not only the overall cost increase of the vehicle but also the cost of repairs. On small sports cars and hybrids this makes a lot of sense to keep them light. But truck drivers tend to USE their trucks and we have a tendency to bang our trucks up…not intentionally but stuff happens. Auto makers should be careful about choosing what parts and panels they want to swap out for more expensive materials on trucks.

The Tundra already has a history of tailgate failures and one TSB out for them. I guess those can’t be any worse.

why can’t the tailgate inside at least and entire bed be made out of composite heavy duty resin (plastic)? It is definitely lighter than sheet metal and yet should be tons cheaper than aluminum which doesn’t hold up very well to dents and dings and I think would crumple and not be as safe as sheet metal.

Our tailgates having way too thin a sheet metal inside removeable piece is not very good and strong, why make it even worse with aluminum? Personally, our tundras cost enough the way they are, no need to make a huge price increase to take us average folks to the poor house.

mk – I have this same thought. Plastic beds work great on the Tacoma…I’d be all about that on the Tundra. Saves weight, removes the need to pay for a bedliner, and they’re damn near indestructible.