UAW Boss Claims F150 Built Faster Than Tundra – WRONG

Jason Lancaster | Jan 05, 2009 | Comments 13

UAW boss Ron Gettelfinger, in an op-ed piece for the Detroit News, recently made claims that union workers are faster than non-union workers. While we certainly can’t speak to that fact (nor would we make such a grand generalization about workers), it’s pretty clear to us that the following piece of information is completely, 100%, incorrect. Laughably so:

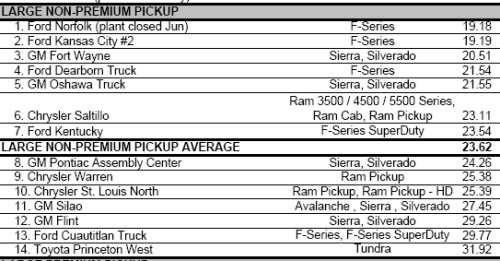

according to 2008 Harbour data, it takes UAW members in Kansas City just over 19 hours to assemble a Ford F-series pick-up. It takes more than 32 hours to assemble the Toyota Tundra, a similar vehicle, at a non-union plant in Princeton, Indiana

Gettelfinger used this little piece of fiction to help demonstrate a point that’s very important to the UAW – the union has given enough in terms of wage and benefit cuts. They don’t think they should have to give anymore.

Fair enough. Far be it for TundraHeadquarters.com to argue with Ron Gettelfinger about the sacrifices of the UAW.

However, when it comes to the “fact” that the F150 can be assembled in K.C. in about half the time a Tundra can be built in Princeton, Indiana, we have some facts of our own:

1 ) If we assume this statement to be true (disregarding all the other information below), the only logical conclusions are that either a) Toyota workers in Indiana are inefficient and lazy OR b) The Tundra is about 68% more complicated than the F150. Since it’s pretty fair to assume the workers aren’t lazy, and since Toyota leads the world in manufacturing efficiency, Gettelfinger’s statement would seem to indicate the F150 is a lot “simpler” than the Tundra. Of course, his statement isn’t true. Still, it sounds like good fun to call the F150 “simple”…

2 ) The 2008 Harbour Report concluded that, overall, Toyota and Honda still lead all manufacturers in terms of productivity by a narrow margin. Even if the data that Gettelfinger cited were accurate, it would seem that UAW plants and non-UAW plants are about equally productive.

3 ) The 2008 Harbour Report is based on data from 2007. The new Tundra was launched in 2007 – of course the hours per vehicle stats at Princeton are going to be out of wack. A lot of worker time was spent learning the new assembly process.

4 ) The Harbour Report doesn’t account for supplier pre-assembly. If half the parts installed on the F150 come pre-assembled from the supplier, the F150’s assembly time is going to be lower. Since the Harbour report doesn’t account for this fact, it’s difficult to make a legitimate comparison plant to plant.

5 ) Finally, according to the same Harbour Research study that Gettelfinger mentioned, Ford’s Cuautitlan, Mexico truck plant rates at 29.77 worker hours per vehicle. How is it possible that an F150 made in Mexico takes 52% longer to build than a F150 made in Kansas City? The vehicles are exactly the same, aren’t they?

The Harbour report shows that F-series built in Mexico take almost 10 hours longer to build than F-series built in Kansas City. Since the F150’s made in Mexico are the same as the F150’s made in Kansas City, something must be left out of this data.

The 2008 Harbour report, based on 2007 data, shows that the Tundra plant in Indiana is the least productive of all non-premium truck plants. Of course, 2007 was the year of the new Tundra launch, so it’s certainly not a fair comparison to the 2007 F150 that was in it’s third year of production. Not to mention the fact that the F150 takes almost twice as long to build in Mexico, a red-flag in terms of the accuracy of the supplied data…

To UAW chief Ron Gettelfinger: Sharing this type of inflated and misleading “fact” is a big part of the reason no one trusts you, the major auto manufacturers, or congress. If you really want to help your members, how about being honest and open with the U.S. public?

Filed Under: Auto News

Thinking is a lost art

Trust me I’m a recruiter……….

Mmmm, interesting that these comments (UAW) describe how quickly they build the F150 and don’t talk quality. Built with a leaky front window that that allows water to fry the electronics; an engine that blows spark plugs; and, a leaky rear window, I can now understand why they have the problems. They build them so quick they don’t bother with proper quality control. Remember, Ford no longer advertises, “Quality is #1”. For more, go to http://www.fordf150news.wordpress.com

Lance – Good points. Nice blog – definitely going to have to follow your posts.

[…] about quality??? Filed under: Uncategorized — oakvillehomes @ 5:51 pm According to the Tundra Headquarters website, Ron Gettelfinger, who is the UAW boss, made a claim in an op-ed piece for the Detroit News that […]

I see your site failed to mention the poor quality of the non union workers building the Tundra.Now all of a sudden the Harbour Research study is all wrong. The same study used against American auto companies for years.

Tundra 4×4 criticized by Consumer Reports; rated “below average” in projected reliability

The first involves the Tundra’s transmission, with at least ten owners at TundraSolutions.com reporting that their trannies experience rough shifts that make the truck feel like it’s riding over rumble strips. The ‘rumble strip’ transmission issue has been acknowledged by Toyota North America and traced back to the torque converter not disengaging properly.

The second quality issue sprouted up this past weekend, also on TundraSolutions.com, and involves tailgates that have been failing or, in some cases, even falling off. The most common experience seems to be the tailgate itself forming cracks and the metal buckling when under load. One owner reported that his tailgate failed when loading an ATV into the bed for the very first time. The tailgate being such an integral part of owning a truck, members of TS have begun an online petition, which they hope will force Toyota to recognize the issue and do something about it

http://www.autoblog.com/2007/1.....ty-issues/

I’ll keep my Ford 135000 mile no problems and the tailgate is still there.

Bob – So you’re saying that not only is the F150 built FASTER, but it’s better BECAUSE it’s built faster? I don’t buy it. The trucks are built in about the same amount of time, and quality is excellent for both. The UAW boss shouldn’t try and use questionable “stats” to prove that the UAW is better…he should be figuring out ways to make certain the domestic auto manufacturers stay in business without help from the taxpayers.

Bob you’re a late reader. The tailgate issue was mentioned a year ago same as your favorite magazine C/R. You also failed to mention the 4×2 was rated above your Ford. Fancy that. Keep digging Bob you might even find out exactly where your truck is made….

ZING!

Kep building union it is the way america works best because the U.S.A. Is the biggest and best union their is

Isn’t it funny Anonymous that the president kick the unions to the curb for this bailout plans.

As far as your “accuracy of data” Mexico makes super duty (F-250 &350) US plants mentioned only make F-150 Different chassis.

Anonymous – You are correct – the F-series built in Mexico are Superdutys. However, the point still stands: the numbers cited by Gettelfinger were fuzzy and more than a little suspect.